How many processes to print LOGO?

2025-04-16 11:00

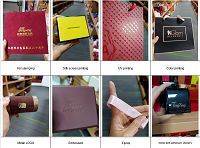

1.LOGO process classification

Generally we have 8 processes for printing LOGO. Hot stamping, silk screen printing, UV printing, color printing, embossed, metal LOGO, metal self-adhesive stickers, epoxy

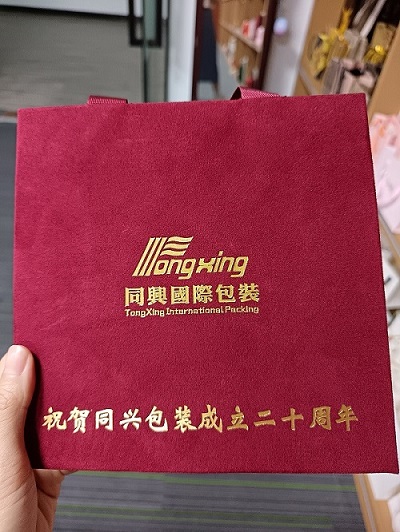

The characteristics of this logo are: glossy, different color changes at different angles, stable craftsmanship, high-end and affordable. And this process requires making a mold version of the LOGO. The machine is prepared with high temperature and high pressure in advance, and the color of the metal foil is printed on the packaging product through temperature and pressure. This process has lower requirements for packaging materials and is used for most packaging materials, except flannel, and leather or paper with deeper textures. On these materials, it is easy to cause the metal foil of the LOGO to fall off, because the surface of these materials is not smooth enough.

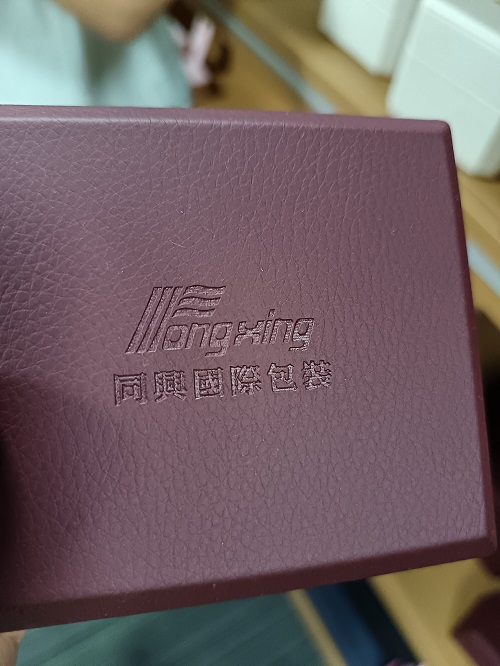

Silk screen printing

This process involves creating a logo using ink and silk screen printing. Therefore, the customer can choose a Pantone color or provide a physical color sample. The supplier can adjust the color to match your needs. Please note that there will be some color deviation, and it may not achieve the exact effect you want, but it can get close to 95% color accuracy This craft is used for wooden boxes, velvet fabric (short pile), paper, leather, microfiber, metal, etc.

UV printing

This process actually involves curing UV ink under UV light to achieve a glossy effect on the surface of the packaging product. This process is also very sophisticated, often used for decoration, and is considered a secondary part.

This process can be said to be the simplest. You only need to create a printed layout, confirm the desired logo position, size, and color. The machine will adjust using Pantone colors or color samples to print the final product. The delivery time for this packaging is very fast because this process can only be done by machine.

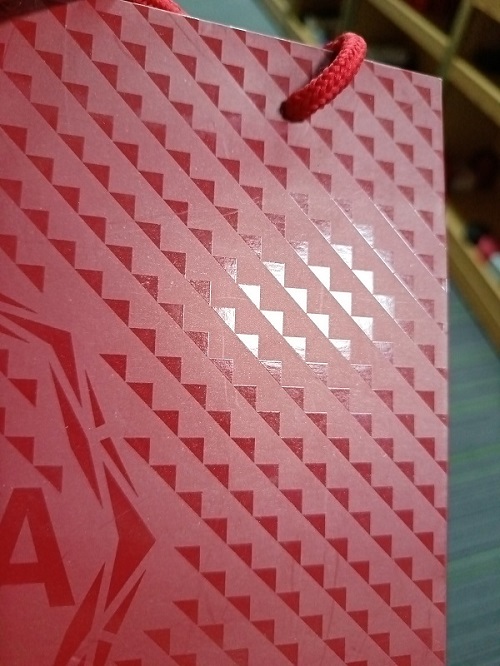

Embossed

This process is almost the same as the hot stamping process, except that the metal foil is removed during the printing process so that the final effect is transparent. This process is suitable for all products, except wooden boxes and metal.

Metal LOGO

This process involves electroplating on a stainless steel material to create a mirror or brushed effect, and then printing LOGO on its surface through silk printing, corrosion, engraving, or stamping

Metal self-adhesive stickers

This process only requires preparing the stickers, positioning them according to the logo's location, and finally sticking them on This logo has a good three-dimensional effect and a metallic sheen, suitable for most products, but not for long-pile fabric as it tends to fall off easily.

Epoxy

This craft is suitable for ribbon because ribbons are mesh, and other crafts are difficult to print LOGO on. This craft can have multiple colors, and the actual effect is clear and beautiful.

2.How to choose the LOGO craft effect you want?

Usually, you just need to choose hot stamping, silk printing, or embossing, as these processes can give you a high-end effect. If you need something cheap or fast, you can choose printing.

If you want it to be exactly the color you want, choose silk printing. If you prefer a metallic look, choose hot stamping or stickers, but hot stamping will be more durable.

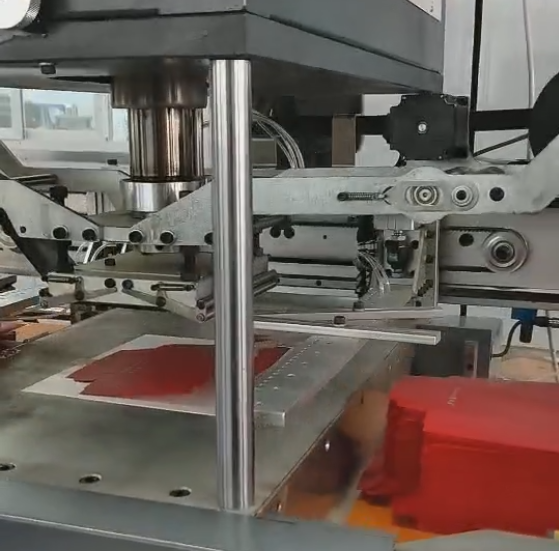

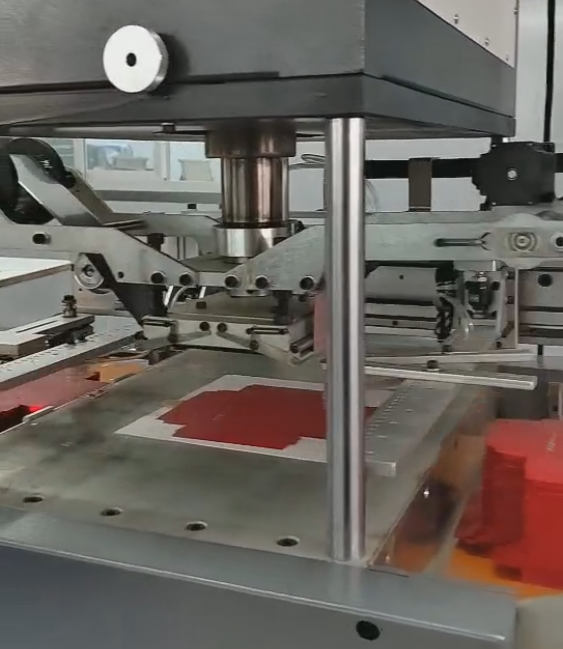

3.Show our LOGO production line

If you like our production, please feel free to contact me.